Basic stranded cast-off

Also known as: Basic stranded bind-off.

Continue reading “Basic stranded cast-off”Basic stranded cast-on

Also known as: Gauge swatch cast-on, Provisional cast on

Continue reading “Basic stranded cast-on”Casting on the Nahanni River (P201902)

This is the second in a series of podcasts on how I knit my Nahanni River vest project. In it I discuss what I found out from my gauge swatch and casting-on and joining-in-the-round for this project.

This is a video. There is also an audio only version:

This my second podcast (more strictly a vlog) in a series in which I explain how I prepared to knit the Nahanni River Fair Isle pattern (designed by Betts Lampers and published by Simply Shetland) (the series is in a playlist in YouTube). In this episode I describe what I found out from my gauge swatch, and explain how I cast-on and joined in the round for this project.

You will have to wait for later podcasts to see how I knit the Fair Isle pattern and made the steeks – and whether the garment fits me!

The video version of the podcast is pubished on my YouTube channel. The sound channel from this is available as an audio podcast.

Links to items mentioned in the podcast

Transcript

The headings in this transcript link to the point in the podcast where that topic starts. This transcript has been edited to correct errors and to clarify phrasing.

Introduction

Hello I’m Steve. I’m also known as TeabreakKnitter on social media. This is my second podcast.

If you watched the first I’m really pleased you came back again, and you also know I’m building this series of podcasts around a project, a project to knit a Fair Isle vest called the Nahanni River by a designer called Betts Lampers and sold by Simply Shetland.

Last time I talked about how I assess the pattern to see what’s in it: for the yarn, for the tools I need and for any techniques I need. Then I went on to talk about how I chose the size that I wanted to knit, and any modifications I might need to it, and I ended up talking about how I started the gauge swatch.

In this podcast what I want to talk about is what I found out from the gauge swatch, talk about how I cast on, and how I join that cast-on in the round. I hope you enjoy this.

Gauge swatch

What did I find out from the gauge swatch? Well, before I show you in detail, here’s the gauge swatch. You see that it has quite a large amount of the pattern on. I’m quite proud of this. If you look at the back of the gauge swatch all the stranding has come out very evenly. It has also been washed and blocked and the wool is now very soft (you can’t I see see that it’s soft in the video, but it is beautifully soft). What I want you to see now is more detaisl of what I found out from the gauge swatch.

This is the gauge swatch for the Nahanni River vest. You will remember that I cast-on [the gauge swatch] using the basic stranded cast-on. I cast-off using the basic stranded cast-off. The cast-on and cast-off are loose, so they don’t actually control the shape and size of the swatch. I also knit this to imitate knitting in the round. I knit as usual from left to right, knit stitches all the way across. When I got to the end I slipped the needle through so that I was ready to start knitting again at the right hand side. I stranded the wool across the back loosely so that I had the wool on the correct side to start. I then knit all the way up. This particular swatch is 48 stitches by 48 rows. When I had finished knitting it, I cast it off the needles and cut the strands that had been across the back so that I could tie them up. Now I’ve got something that is flat that I can measure. I find it very difficult counting stitches, counting across columns or counting the number of rows. I only wanted to do that once, even though I’m going to be measuring this swatch several times. To help me do that, I’ve run threads horizontally and vertically using very thin contrasting colour yarn so that I can see them. That means I know how far it is, or how many stitches there are, between the two sets of threads, which means all I have to do now is measure that distance in order to work out the gauge.

The first time I measured this [swatch] was when I had taken it straight off the needles. I took it off the needles, put these threads in and measured the distance across and the distance up and down between the threads. That gave me what is called my “off the needles” gauge. For this particular swatch this gave me 34 stitches to 10 cm and 30 rows to 10cm. As I knit the finished item I expect that’s the gauge I would get if I use the same needles. Once I had done that, I then blocked the swatch. I put it in warm water with a little bit of wool soap mixed in with it for about 2 hours to let the wool really soak, relax and let the fibres work out how they actually wanted to lie. Then I took it out, I squeezed it taking care not to stretch or strain the gauge [swatch], wrapped it in a towel to support it and then wrung the towel out to get as much water as I could out of the swatch. I then laid it on a blocking tile, smoothed it out, pinned it where it wanted to be, and left it to dry. When it was dry, I measured again between the two sets of threads.

This time my gauge was 32 stitches but it stayed at 30 rows. So what does this tell me? Well, the first thing it tells me is that my stitch gauge changed. I got fewer stitches over the 10 cm distance after I’d washed this swatch than I did before. That means that it’s going to be a little bit wider after I’ve washed the garment than before. But the row gauge remains the same. The gauge I want to use to compare against the pattern is the gauge it is now after blocking. So 32 stitches and 30 rows. I did leave this a few days and came back and measured it again and the gauge has changed slightly. The stitch gauge remained unchanged at 32 stitches for 10 cm but the row gauge tightened up very slightly. [10 cm = 4 inches] It is now 32 rows over 10 cm rather than 30 rows over 10 cm.

How does that compare with a pattern? Well, the pattern is asking for 32 stitches along a row in 10 cm. That’s exactly what I’m getting. It asks for 34 stitches up and down (that’s 34 rows) over 10 cm. I’m actually achieving 32 rows after it has relaxed. So I’m knitting a little bit more loosely than I was before. I’d expect my finished garment to be the same width as in the pattern, but I’d expect it to be slightly longer than in the pattern.

If you recall, I was looking to make this jumper for this vest slightly larger than the size in the pattern. Actually, it is going to be slightly larger, so I need to do a bit of calculation to find out how much larger is going to be.

What I found out from my gauge swatch is that my gauge is the same stitch gauge as in the pattern, but the row gauge is slightly different. This means that my sweater should come out slightly longer than that in the pattern, which is good and is what I wanted. But how much bigger? Well, here is how I do the calculations to find out how long that sweater is actually going to turn out to be.

What does this mean for my finished garment? Well, the pattern is going to produce a garment of length 24.25 inches, but if I knit as I knit in my gauge swatch, I will actually get something that is 25.77 inches. That’s about an inch and a half bigger than the designer made in the pattern, which is about the extra length that I was looking to make. This means that I won’t need to add that extra motif on the bottom of the knitting. I can just knit according to the pattern and I will get a longer vest than in the original. So my gauge swatch was actually really useful. Of course it let me see what the pattern would look like in reality, although I only knit the gauge swatch in two colours rather than the full range used by the full pattern.

It also told me that I don’t actually need to add any pattern repeats on, because I’ve got a different row gauge than the on the designer got, and so my vest is going to be slightly longer. In fact that “slightly longer” is exactly the length that I was aiming for. So provided that when I need the project as a whole I’m knitting to the same gauge as I knit the gauge swatch, vest will end up the length I would like it to be. That’s really good.

The gauge swatch was really valuable in confirming that I’ll get the right width for the vest and the right length, and that the pattern would look good in the wool. Also the finished fabric had a really good feel to it.

That’s the gauge swatch.

Casting on

Now I want to talk to you about casting on.

The cast on used in the pattern is new to me. The German twisted cast-on is sometimes called the Old Norwegian cast-on or the twisted knit half hitch cast-on.

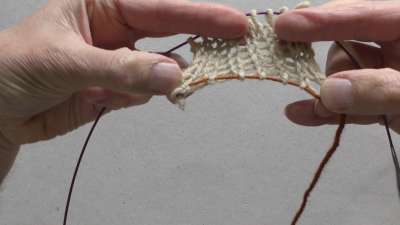

If I tried to show you the cast-on using the yarn in the project, you wouldn’t actually be able to see because the yarn is too fine to show up in a video. So in the short section of video I’m going to show you I’ll be using thicker yarn so that you can see what’s actually happening in the cast-on.

I’d like to show you the twisted knit half-hitch cast-on. You are using one piece of yarn. One end (this is the end of the yarn) is the tail end, and you want 3 or 4 times the width of your garment for the tail end. The other end is the yarn that’s attached to your ball and that will become the working on for the rest of the garment. I’ve just tied together two different coloured yarns here so that it is easier for you to see in the video which is the tail end and which is the working yarn.

You start off by putting the tail end over your thumb and the working yarn over your forefinger, holding the ends in your palm with your other fingers. For this is very first cast-on stitch you come up underneath the strand, bring it forward in front of the tail end, back past the other side of the tail end, into the middle; bring your needle up and bring it forward, put it through the loop (still working on the tail end), turn it round so it is now pointing towards the back, put it under the working yarn and now, with the tip of your needle underneath that little cross of the tail end, see that little cross there, and now you can leave go. And pull it.

Again. Take the tail end, catch it on your thumb, needle to the front, under the tail end nearest you, up the middle, over the tail end farthest from you, keep it going round in a circle, under the working yarn, and back, through and under that little cross at the bottom.

Forward, under, back, up, through the loop, back, under, and through the loop under the cross.

There is an alternative way of doing it that starts off the same but I find a little bit easier at the end.

So, again, keep going forward, back, up, through the loop (we are just exactly the same at the moment), under the working yarn. Now, instead of going through that little cross there, you undo that loop by rotating your thumb so that it is now a plain straight-forward loop that you can just throw over the end of the needle.

So, forward, back, thorugh, back, round, undo the cross and loop over the needle like that.

So, forward, back, forward, through, round the back, undo the loop by turning your thumb round, like that.

So just comparing the two again.

The first way. Forward, round, through the hole, round the back, under the working yarn, and through that little crossed bit at the bottom.

That one again: under, back, through the hole, under, over, and through the hole beneath the cross.

And the second technique: forward, back, through the loop, back, under, rotate your thumb, and drop the loop over the end.

And again, forward, back, through the loop, back, pick up the working yarn, rotate your thumb, and drop the loop over the end.

That one slipped off the top of the screen, didn’t it! Like that.

So, [there are] two ways of doing the cast-on. Both produce the same result. And that is the twisted knit half-hitch cast-on.

Marker thread

That’s how I’m going to do the cast-on for the final vest, but there is one additional thing I want to do to make myself ready for joining in the round. That is to place a marker thread while I’m doing the cast-on. This marker thread serves two purposes. The first one is to tell me how many stitches I have cast-on, because the pattern calls for more than 300 stitches being cast-on, and I’m just not that good at counting. The other purpose is so that I can see whether the cast-on has wrapped itself around the cable when I come to do the join. It will tell me whether the joined cast-on is twisted. Because if I twisted the join then the final sweater wouldn’t actually work out as a sweater, it would work out as a mobius strip – which is not very good. Using this technique of putting in a marker thread solves these two problems. It lets me mark every (in my case I’ve chosen) 10 stitches, so you can easily count the number of stitches (because I can count 10 stitches quite reliably) and I can count the number of groups of 10 quite reliably. It also lets me, when I come to join in the round, see that the cast-on hasn’t wound itself around the cable.

Again I’ll show you this technique using thicker yarns before you see the final version from the project.

I’d like to show you how to use a marker thread to help you count your cast-on stitches and also to help you avoid twisting your cast-on when you join it in the round. I’m using two threads. The first is the working yarn that’s going to make the fabric, and the second is a contrasting colour that I’m going to use for the marker thread. Normally the marker thread will be thinner and smooth. Thinner so that it doesn’t space out the cast-on, and smooth so that you can pull it out easily when you finished with it. But for this demonstration I’m using a thicker thread so that you can see what’s happening.

For the cast-on you start as normal. Give yourself enough tail if using a long tail type cast-on, and hold it as you would normally hold it for your cast-on. Here is the marker thread, and I’m going to hold that in my right hand so it’s ready when I need it. The first thing I’m going to do is cast-on 9 stitches. This is the twisted knit half-hitch cast-on. One, two, three, four, five, six, seven, eight, nine. I’m going to be using the marker thread to help me count stitches, so I’d better make sure I really have 9 stitches on there. 1, 2, 3, 4, 5, 6, 7, 8, 9. I have 9 stitches on the needle. Here is my marker thread. I slip it so the tail end [of the marker thread] is at the front and the working end [of the marker thread] is at the back, and it’s now between the end of the needle and the last stitch. Now I cast-on my tenth stitch. So I’ve now got 10 stitches on the needle. I move that marker yarn round the needle to the front.

I now cast on another 9 stitches. One, two, three, four, five, six, seven, eight, nine. Let’s count that up: 1, 2, 3, 4, 5, 6, 7, 8, 9. Yes, there are nine stitches. I run the marker thread loosely across the front of those, round the back of the needle. Not a yarn over, just slipping it round keeping it below the needle. I do my tenth stitch, and bring the [marker] yarn back to the front, around the bottom of the needle. So you can see what’s happening. I’m catching the [marker] yarn every 10th stitch. I’ll just do one more group: 1, 2, 3, 4, 5, 6, 7, 8, 9. And again check the 9 stitches: 1, 2, 3, 4, 5, 6, 7, 8, 9. Move the [marker] yarn to the back, do my tenth stitch, move the [marker] yarn to the front and keep going. I’ll just put on one more stitch to keep that yarn in place.

So, we have got the marker yarn forming a nice line along the bottom of our cast-on edge so that if we managed to twist it somehow when doing the join in the round, it would be quite obvious. You’d see the marker thread quite clearly if it went round the needle. And the other thing is now to count the stitches, all you have to do is count where marker yarn disappears. So 1, 2, 3; 30 stitches. So that’s how to use a marker thread to help you count your stitches in a cast-on and to help you avoid twisting your cast-on edge when you join it in the round.

That’s how to insert a marker yarn into the cast-on. What does it look like for the project? Well, it’s easier to show you this in a photograph.

That was my cast-on for the project.

Joining in the round

Now I need to join that in the round so it goes around as continuous circular knitting. There are two things to remember when joining in the round. The first is you don’t want to twist that cast-on, which is why I put the market thread in so I can spot if it that’s happening. The second one is that you find when you do the cast-on you can get a jog where the two ends of the cast-on meet in the round. I’ll show you a technique, one of many, that allows you to remove that jog, so that when you look around the bottom of the finished item you can’t actually see where that cast-on joined.

I’ll show you how I cast-on in the round when I’m working on a piece that has a very large number of stitches. I’ll be using a twisted knit half-hitch cast-on and, for this demonstration, because I’ll not be [actually] casting on a large number of stitches, I’ll also be using the magic loop for circular knitting.

You can see here that I’ve got 3 yarns. This top yarn is the working yarn. It will go on to form the fabric. The twisted knit half-hitch cast-on is member the long tail family, so I need a tail-end yarn, and I’m using a separate ball of yarn of the same type as the working yarn for the tail end. The reason for this is that if I’m casting on a very large number of stitches, I don’t want to run the risk of running out of tail end because I’ve not left enough room. The third yarn can see is a marker yarn. For the purpose of the demonstration this is the same size as the working yearn. I would normally use a thinner yarn and a smooth yarn because it doesn’t play any part in the actual fabric. It is just there so I can see where the edge is and to help me count the stitches. If it is smooth it is easier to pull out from the finished item. I want to remember which is the working yarn and which is the tail end, so I just slip a stitch marker onto the tail end. It doesn’t have to be a removable marker because before we start knitting the body of the fabric, we will be snipping off the tail end yarn, so the stitch marker will just fall off the end.

Normally with a long tail family cast-on, you’d use a single piece of yarn for both the working yarn and the tail end, so the first step is to make that single piece of yarn. To do that I’ll leave enough to sew in the ends and make a slip knot just to join those ends together. I’ll then place them on the needle to hold them so they don’t slither all over the place. Again, the marker yarn (I don’t need to sew in in the end of this) but I want to stop it moving around so, again, I create a slipknot and fit it over the end so that’s just held in place, so I know where it is. Because I’m using the decrease type of join [in the round] I need to create a stitch that I’m going to join with the last cast-on stitch. I just need to create a simple loop so that this, which would be tail end if you used a continuous piece of yarn, is at the needle end of the loop. So a little loop with working yarn coming out from behind the loop.

I now need to start casting-on. I’m going to cast-on and place a marker every tenth stitch. I will start my cast on; 1, 2, 3, 4, 5, 6, 7, 8, 9. I want to mark every tenth stitch. I just bring the marker around here, wrap it round the end, and placing it behind there. Then I cast-on a tenth stitch and bring it [the marker yarn] to the front. And again 1, 2, 3, 4, 5, 6, 7, 8, 9 … place marker stitch … 10. That’s 20 stitches cast-on. I’ll continue until I’ve cast-on cast on 64 stitches.

So, there we are, are 64 stitches cast-on.

I’ll now snip off this extra marker thread, and I’ll cut off the tail end thread, so I’m carrying less ends. I’ll put a knot in the end of that to keep it tidier. There are my 64 stitches. 10, 20, 30, 40, 50, 60, 1, 2, 3, 4. I now need to join these in the round to form a circular piece of knitting. I take the working yarn around to the back so that the needle with the working yarn is pointing from left to right. And the other needle is also going to point from left to right. I’m going to use magic loop, so I’m going to need to split the cast-on in the middle. So, there’s that first loop that we had, so 10, 20 30, and I want to split it at 32 stitches. The reason to split at the 32 is that I’m going to continue in rib, and so I would prefer to have to join at this end of the magic loop and at the cast on end as a join when I’m transferring from a purl to knit stitch. I find my ladders are far better if I do it that way round.

So, we now have stitches on each needle. If this was not a magic loop and I had a shorter cable, they [the stitches] would just be going around like that. You need to make sure they [the cast-on stitches] are not twisted which is the next use for this market thread. You can see it’s there running along the bottom, and it’s quite visible. If I’d managed to twist the stitches round, the marker thread just disappears around the needle.

I’m ready to start to join in the round. The first thing that I want to do is to take that extra loop and put it onto the needle at the back. To get to it I take those two slipknots off, and I want it [the extra loop] to go in front of the working yarn, so the working yarn wants to be behind it. And just slip that down to join the other stitches. I can now start knitting. I’m knitting in rib, so knit, knit. Give a bit of a tug. That will help tighten up the stitches so you don’t get laddering, and my purls. I’ll keep going all the way around until all the way round until I get to the last four stitches.

I’m now at the end of the first needle in the magic loop. So I pull the needle through, and I need to make sure that I’ve not twisted this. I put the needles together and the marker yarn hasn’t twisted over, so that’s good. I now continue knitting towards the end.

I’ve now reached the point where I have got four remaining stitches plus that loop on my needle. I just want to knit, knit, purl. And here’s the final stitch, and the loop. I want to join these together in a decrease that, because it’s a purl stitch, is a purl decrease [p2tog].

Now we’re ready to start the next round of the knitting. Yet again I just need to check that I’ve not twisted the [cast-on] stitches and so I check that the marker a thread is all the way along the bottom. What we can do is just put the marker thread through there because, remember, we didn’t have it going through at the start of the knitting [round]. I’m putting stitches onto the needle that receives them and pulling the the cable so that stitches on the back are on the cable. And we start again.

And so, there we are, at the end of the second round, all ready to continue knitting with the rest of the pattern.

That was my cast-on and join in the round for a project with a large number of stitches.

That was how I did the cast on.

Looking forwards

In this podcast I talked about the gauge swatch that I used to help me prepare for my project, and I talked about how I cast-on and joined in the round to start off the project.

Next time I’ll be talking about the corrugated rib, that is the first section of the pattern.

Until then happy knitting!

Project planning – the Nahanni River (P201901)

This is the first in a series of podcasts on how I knit my Nahanni River vest project. In this podcast I explain how Iread the pattern to find out the yarn that I’ll need, any tools that I need and any techniques that I will need to learn to knit the pattern. I also talk about how I choose the size I want to make for the finished product, and how I do a gauge swatch for a project that will be knit in the round.

This is a video. There is also an audio only version:

This my first podcast (more strictly a vlog). In it, I explain how I prepared to knit the Nahanni River Fair Isle pattern (designed by Betts Lampers and published by Simply Shetland). I look at how I read the pattern to find out about the yarn, tools and techniques that I would need to use, how I decided on the size I wanted to knit, and how I created a gauge swatch to check my decisions.

You will have to wait for later podcasts to see how I got on with the project and whether the approach I planned in this podcast works in practice!

The video version of the podcast is pubished on my YouTube channel. The sound channel from this is available as an audio podcast.

Links to items mentioned in the podcast

Transcript

The headings in this transcript link to the point in the podcast where that topic starts. This transcript has been edited to correct errors and to clarify phrasing.

Introduction

Hello, I’m Steve Foreman, known as TeabreakKnitter on social media.

This is my first podcast, and I thought that I would like to show you my thought process as I go about preparing and knitting a project. In this first podcast I am going through the planning stages.

The project I want to talk about is the Nahanni River vest. I purchased this [as a kit] at the Edinburgh Yarn Festival 2019. It is a Fair Isle project, and I bought it as a kit because I liked the colour scheme.

What I want to talk about in this podcast is how I read the pattern to find out the yarn that I’ll need, any tools that I need and any techniques that I will need to learn to knit the pattern. I also want to talk about how I choose the size I want to make for the finished product, and how I will do a gauge swatch.

Choosing the yarn

So, I have chosen the pattern and now need to read it to find out what I need to know.

The first thing to find out about is the yarn. One easy way to choose the yarn is to buy the pattern in a kit with all the yarn you need for it. Job done. Or, almost job done.

Let’s say that I’ve chosen the pattern and cannot get hold of the recommended yarn,

or I don’t like the colours in the recommended yarn, and I’d like to use a different set of colours. What do I need to know about the yarn to make a substitution?

The first thing is the type of yarn. In the UK we talk of 4-ply, DK, aran. This pattern used what is known as a 4-ply yarn (although I think the yarn is only made from 2 plies). It is the UK 4-ply weight (US fingering). On the ball band it gives us the gauge that the manufacturers think it will knit up to using the recommended needle. This information is also held in the Ravelry database, so it easy to look up other yarns that knit to the same gauge. Another thing that is important because I am knitting a Fair Isle project is that I want a yarn with good stitch definition. There is no point spending a large amount of time creating all those detailed patterns if what you end up with is all the colours merging into one, not contrasting, or being hidden behind a huge fuzz of wool. You want a wool that is going to show up your patterns well, which means using a wool with reasonably good stitch definition.

Skipping ahead, this pattern uses calls for you to “steek”. Steeking puts fear into the hearts of a large number of people because you are cutting into all that lovely fabric that you have just made. It is not as scary as it sounds, and when we come to a later podcast I’ll show you what I do when I’m steeking, but that’s looking several podcasts ahead from now.

But for now, what you need to know for your wool is that you want it to be slightly “sticky”, so, not absolutely smooth and slither everywhere, but that holds together a bit so that when you knit a few stitches and take them off the needle they still stay there and it takes a bit of pulling to pull them apart. When it is washed and worn, that means that the wool tends to bind together quite well over time. This stops the steek pulling apart. You don’t want wool that felts so easily that as soon as you look at it you get felt,

but you do need wool that clings a bit to itself, just to give that bit of encouragement to the steeks to stay put until the fabric has been worn a bit.

So, those are some qualitative aspects as well as the quantitiative aspects like the type of wool and the gauge it knits to. You also need to know how much weight there is in a ball of wool of your alternative (the recommended Spindrift comes in 25g balls) and how much length there is in a ball. This one is 105m, your substitute could be something different. But if you are looking to substitute with a wool and you find

that a 25g ball has a substantially different from 105 metres on it, then you want to start being a little worried that it is not going to knit up in the same way as the recommended yarn. If you get more length, then that wool is either going to be a lot thinner, or a lot more “open weave” or lofty than the Spindrift. The finished garment won’t have the same sort of drape, it won’t have the same sort of characteristics as this wool.

However, I’ve got it easy. I’m knitting with the recommended wool bought in a kit, so I should have enough wool, and it should knit up nicely.

Choosing your tools

The next thing I am going to look for in the pattern is what tools I need. Have I got the right needles? In this case, yes. But this particular pattern asks for me to use two circular needles of different length with 2.75 mm tips, and two circular needles of different lengths with 3.25 mm tips.

That’s not a problem, but the reason it asks for two different lengths is because as you knit you will change the size as you go up the body and do the steek, you will get fewer and fewer stitches per row [round] when you come to the armholes, and keeping the same length cable would mean that those stitches would be really stretched out. So, in the pattern it suggests that you change to a shorter cable so that those stitches still fit nicely around the cable.

I plan to keep using an 80 cm cable for this because I use the magic loop techniques (magic loop, travelling loop), which means I can knit as small a number of stitches on the needle as I like and still be able to continue with that same needle. If you find that you have problems with laddering when you do that, you might well want to change to a shorter needle. So, I’m quite happy to use two circular needles, one with 2.75 mm tips and the other with 3.25 mm tips. The larger one is an interchangeable, so if I do need a shorter cable changing is easy.

The other thing you find when you read through the pattern is that at some stage I am going to do a three needle bind-off. For a 3 needle bind off, I will need 3 tips. I need to make sure that I have another 3.25 mm tip available for doing that. An alternative is to make sure that I have some smaller tips that I can transfer the work onto, and use one of the 3.25 mm tips for doing that bind-off. But I need three needles of similar size for that bind-off. I just need to make sure that I have those extra tips available when I need them.

The pattern also calls for stitch holders (I have plenty of those).

And it calls for a coil-free safety pin to hold one stitch. Well, the stitch MARKERS I use are the ones that look like tiny little padlocks, so holding a single stitch on one of those is going to be really easy. I don’t have one of those on the desk in front of me, but in later podcasts when I am showing you my knitting you’ll see dozens of those stitch MARKERS lying around the various bits of knitting that I have. Of course, if you haven’t got one of those stitch MARKERS (I’m looking down at my desk) – there’s always a good old paperclip that you can pull out and use to hold a stitch.

Identifying the techniques

The last thing I am going to look at in the pattern are the techniques. Which techniques do I need to learn?

Let’s start in the very beginning with the cast-on. This pattern calls for the German twisted cast-on. I needed to do an internet search to find out what that is and I found that it is also called the Old Norwegian cast-on and the Twisted Knit Half-hitch cast-on.

I’ve done some research to find out how that is done, and looked it up in the “bible”

the Principles of Knitting by June Hiatt. This is a really good book. It’s a little bit … heavy … but in doing the decades of research for that book the author found that the same knitting techniques were called by different names around the world. That should be no surprise, as I’ve already told you different names for the same cast-on. She used a naming technique that tries to be independent of those old traditions and describe what you are doing – hence the twisted knit half-hitch cast-on. On my website I am trying to use that independent description to try to remove the associations with different knitting traditions that could be confusing.

A bit like the English/Continental way of describing how you hold the yarn when you are knitting. It’s not particularly English, and it’s certainly not continental. Some people in contenental Europe use what is called the English technique if that is how they were taught in their community, and in England people use the continental method

if that is how their commnity was taught. A lot of these names are meaningless in themselves, so in writing the reference book, the author tried to come up with a terminology that was fairly straightforward. Another example of terminology that can cause confusion when I read a pattern is when a pattern refers to the “right” side. Is that the side that is pretty and looks nice when you have finished your knitting, so in stockinette the nice smooth side, not the ridged side? Or is it the right-hand side of the finished product? And some times, patterns can be confusing. The author decided to use the terms “outside” and “inside” to describe the different sides, the different faces, of the knitting. But that’s a bit of an aside.

You will find on my website that I am trying to use the terminology in this book, where I can, but I do slip into using the terminology I have learned over the past few years as I’ve been learning knitting through the internet.

The other technique, that I’ve used before, but many people are coming to new, is stranded, or Fair Isle, knitting. Fair Isle is a particular type of stranded knitting. This is where you are knitting with more than one colour in one row, and you alternate so many stitches of one colour with so many of another and it goes right the way round. So you are using the colours all the way round. In Fair Isle it is only ever two colours in a row.

Other types of stranded knitting can use more than two colours. The big advantage of Fair Isle knitting is that if you are comfortable in knitting in both the English and the continental methods, with the yarn held in the right hand and also in left hand, then Fair Isle can be knit with one yarn in one hand and the other in the other. Some people hold both yarns in the right hand, others both in the left. Some will hold one yarn with the other lying on the table in front of them and when they change colour they swap over the yarns. It doesn’t matter so long as you get the fabric that you like. You can use any technique you like. I’ve used Fair Isle before, so it is not a technique that I need to learn.

The other technique, that is even more frightening to many people than Fair Isle,

is “steeking”. Steeking is where you have your fabric and you just knit round and round and round. So for a sweater you’d knit round and round and round, past the armholes and up to the top. And you make the armholes by cutting down that fabric. In a later podcast I’ll be taking about the steeks for this particular project, and that includes how you stop those cuts fraying back. But if you are using a yarn like a traditional shetland yarn, good Shetland wool, those steeks don’t need an awful lot of help to stop them fraying. They do not fray. The yarn holds itself together so well that you make those cuts and the fabric stays as it is.

All these techniques are referred to by my website and are linked from the show notes for the podcast.

Choosing the size

I have gone through the pattern, seen the yarn, the tools and the techiques. The next thing to choose is which size of the pattern I want to make.

I’m tall, and like my jumpers and vests to be longer than the average might be – otherwise I get a gap in the middle that can get cold in winter! I also need to be careful to make them wide enough, we all do, but for Fair Isle it is particularly important because there is not a lot of stretch in Fair Isle fabric, so you have to knit to the ease you want. It needs to be big enough to fit with enough space, and in my case I like to put a shirt on underneath without it being too tight.

The easiest way to do this is to find out what ease you really want, and to choose the final measurement you are aiming for, is to use a jumper (or other type of garment you are knitting) that you are really happy with the fit of. I measure that item and say that is the finished size I want to aim for in the garment I am about to knit. In this case, several years ago I knit a Fair Isle jumper, called Raga also sold by Jamieson’s of Shetland coincidentally, and that one fits, but a bit too snugly for me, particularly now that I have put on a bit more weight around my tummy.

So, this one I want to be probably 43 inch chest, to campare with the pattern that gives 42 inch or 45 inch chest. 43 inches is about 110 cm. As I said, the pattern gives me 42 or 45. I know I don’t want this to be tight, so I’ll make the 45 inch chest. Thats going to be about 115-116cm when finished.

The pattern tells me that if I knit a 45 inch chest, I’ll get a 24.25 inch length. That’s about 1.5 – 2 inches, say 4-5 cm, shorter than I would like ideally. So I’ll try to aim for a finished size that is a bit longer than that. To get the extra length isn’t just a case

of doing a few extra rows of stickinette, because you have a Fair Isle pattern. I don’t want to put the extra length in the ribbing at the bottom, because then the ribbing will become too prominent.

If you look, those extra 5 cm or so are going to be one pattern repeat of the major [motif] below where you start knitting in the design. The design calls for you to start at a particular point in the chart. If I started off with the motif below that then I would get about the 2 inches. But all that is dependent on what I’m going to talk about next, and that is the gauge.

Making a gauge swatch

The designer has designed the pattern using their own knitting style and standards, they have had kntting testers try out the pattern to make sure that it is right, and publishers can also have their “little thing” in the gaugethey may have standard gauges, that they think an average person would knit in that wool. The pattern in a guide line. The gauge is what the designer got, or the test knitters got, or the publishing house thinks you should be able to get. You need to test what you do against that.

If you are knitting a scarf, even a cowl, it doesn’t matter. But if you are knitting a sweater or a non-stretchy hat, or anything you are going to wear, or gloves, then it does matter what the gauge is. Because you’ll either find that you have something that is far too big, and falls over you, a hat that is always falling over your eyes, or too small like a sweater you cannot get over your head. The gauge is important, so we need to do a gauge swatch.

I’ve put some references on how to do a gauge swatch on my website, but I’ll put the link below on the screen as I’m talking.

The gauge swatch has to be big enogh to make a judgement. Everyone talks about a 4 inch (10 cm) gauge. That’s what ball bands talk about. That’s not quite big enough to do what you want. If you are dealing with a pattern, like this Fair Isle pattern, there’s a rule of thumb that says, across a row you want to have two pattern repeats. So that the variations is size as you knit groups of one colour togetherin a small number of stitches and then another average out; it is particularly important with cables that pull together very differently from the stocking stitch or garter stitch around them.

In this one [pattern], the pattern itself recommends that you use the pattern (motif) in the chart. This is good, because it means that the gauge you get, you can compare directly with the gauge in the pattern to see how things are going to work out.

The other thing is that this pattern is knit in the round. That is, you are on a circular needle and you keep going round and round and round. This means that you area always knitting stocking stitch, and your stocking stitch is made only of knit stitches – which is great! Most people refer just doing knit stitches over purl stitches. Most people find that their gauge in knit stitches is different from their gauge in purl stitches.

Why does this matter?

If I was to do a gauge swatch knitting flat and knitting two pattern repeats to the gauge here in the pattern, that would be a 15 cm swatch, which is what we want to aim for (that’s 6 inches). So its the 4 inches that you are going to measure the gauge over,

plus a couple of inches (2.5 cm either side), to avoid all those little stretchinesses and unevenesses around the very edge of the knitting that would upset your measurement.

We are going to try [for the swatch] to mimic what we are doing when we knit in the round. This means I can’t knit in one direction and purl in the other to do it flat, because the gauge would be different from when I am just doing knit stitches. There’s a link below to how you can do this. Effectively, what you do is knit one row, 15 cm, and instead of turning to purl, you slide all your stitches back along the needle to start again

but the wool is at the wrong end. You loop the wool loosely across the back, and you knit the next row. Slip it back, loop the wool round loosely, and knit again. You end up with nice even knitting on the front, and a right mess of strands of wool at the back.

When you have knit your gauge swatch, you can then bind it off loosely. All the strands at the back you cut in the middle and tie them off loosely on the edge to stop them coming totally undone.

Then you can handle that gauge swatch. The first thing you want to do is to measure the gauge as it has come off the needles. You take a 4 inch (10 cm) area – count how many stitches there are as you go across in a row, and how many rows as you go up 10cm. That is your “off the needles” gauge, and you need to make a note of that because that is the gauge that you will see as you are actually knitting. So if, as you are knitting and you relax into your knitting, and your fingers take over from your brain in controlling how the knitting is going to go, if your gauge changes you’ll be able to see how it has changed against the gauge swatch.

But that is the first part of the story, and that’s the bit of the gauge swatch that you need as you are going through to make sure your project is actually working out as you planned it. The second stage you have to go through is whether your gauge swatch matches the gauge in the pattern. To do that, you need to do a bit of processing (a posh term!).

Soak it [the gauge swatch] in water, perhaps with a little bit of wool-friendly detergent in there (ie soap) for at least 20 minutes, 2 hours might be better. Then you bring it out and squeeze it dry to get most of the water out – don’t twist it, don’t stretch it – and I then roll it up in a towel and wring the towel, so I’m not stretching the wool, but I’m pushing the water out as much as I can, because I don’t want it to be sitting around in the air too long wet, particularly if it is cold weather when that water is going to take a long time to evaporate. When I have done that I take it out of the towel, spread it out on a blocking pad which you could pay a lot of money for, or you buy children’s play tiles that are a lot cheaper, even if you buy them in local shops they are a lot cheaper than kniting blocking tiles. They do the same job. Lay it [the swatch] out on the tile, pin it loosely at the size it wants to be, let it dry and see what you get. That will give you the finished gauge. That’s the gauge you will actually get fo the finished garment after it has been washed. That, of course, is what you are interested in, becasue that is what you are going to wear. Again, count the number of stitches and rows across the 10 cm square. Compare that with what is in the pattern. If it is the same, it’s good.

If it is different, you could do a bit of arithmetic to find out whether the garment is going to be bigger or smaller, and how much bigger or smaller and is that what you would like to have.

Remember, in my case I could not get the exact size from the pattern, so it might be that my gauge makes it worse and I might need to change the size I was going to make, or it makes it better, or I might decide that it is knitting up too tight and I’m going to use bigger needles. Then I would swatch again with a bigger needle size. Or it it is already too loose, or I don’t like the fabric, it’s a too floppy fabric, not dense enough, in which case you need to try swatching again with a smaller needle.

That’s the other thing, it’s not just the size, though that’s important, but you also want to know whether the fabric feels right. Whether it is soft enough, whether it is too airy, whether it is too tight. The gauge swatch will tell you that as well. When you have done the gauge swatch you will have this information about how the fabric feels, about the stitch gauge, the row gauge. You can finalize your choice of needles and which size of the pattern you want to make.

I’ll now cut to a bit of video showing the start of the gauge swatch and some preliminary conclusions that I am drawing as I go through that. When I come back from that, I’ll talk about what I am going to do in the next podcast.

Starting my gauge swatch

I’m 4 rows into the gauge swatch for the Nahanni River vest.

First I’d like to explain to you what all the various bits of yarn are. The very first bit is Spindrift yarn of the same type but different colours from the ones I’ll be using in the main vest. On the right, this is the tail of the cast-on yarn. This is the tail of the contrasting colour, and these two [at the top left] are the working yarn. In the middle here we have the swatch, very small at the moment, and of course is stockinete – and is curling up.

As you can see, and may have guessed from the two colours, this is being knit in the Fair Isle pattern used within the vest. This gives me practice at doing that pattern, and also means that my tension will be the same as in the final garment.

To achieve that, I need to imitate circular knitting, rather than flat knitting, in the gauge swatch. Because if I was to knit this flat, I would have rows of knit and I’d have rows of purl. Like most people, my gauge is different if I knit purl than if I knit a knit stitch. The way I do that is to knit as normal from the left onto the right needle and when I have finished I slip back again so that I am ready to start again, moving from left to right needle again. And I just drape the working yarn across the back loosely so that it doesn’t pull tight. That’s what all these loops of yarn are at the bottom here. If I find this gets too complicated and in the way, I can just snip them and tie them in a knot on the side. They won’t come undone, particularly because it is a clingy yarn, which is just as well because the pattern will call for me to steek it later anyway.

So, how is it going?

Well, I started off with a very very stretchy cast-on. It’s so stretchy that it doesn’t put any constraints on the swatch, onto the size. This is the basic stranded cast-on. I have done 4 rows of enough stitches that I get a swatch big enough to measure against. You normally measure over [at least] a 4 inch sample of your fabric, (4 inches is 10 cm). This means that if you are going to measure over that amount, you have to have a bigger swatch to select the centre portion. That is particularly important for one of these swatches that is imitating circular knitting,because the stitches around the edge of this type will be particularly different from the stitches in the middle. That applies to all swatches – the edge stitches are always slightly different from stitches in the middle. But it is particularly important when you are imitating circular knitting.

I wanted to make this swatch about 6 inches wide, that’s 15 cm, so I used the gauge in the pattern [to calculate how many stitches I needed], and cast on the appropriate number of stitches to get something that is 6 inches wide. In this case, it is 48 stitches, which happens to be two pattern repeats. I’m now following two of the rules of swatch knitting.

The first rule is to knit it bigger than the area you want to measure, which I’m doing because I’m making it half as big again, and the second rule is to knit using a stitch pattern representative of the stitch pattern in the finished garment, because that way you will be knitting something that you can compare. And also, you need to do more than one repeat of the stitch pattern, because the tension will vary over the stitch patten. Perhaps not so much over a Fair Isle style stranded knitting, which has short floats, but if you are using longer floats or using cables, you will certainly get the tension varying across the pattern, so you want to be able to average that out.

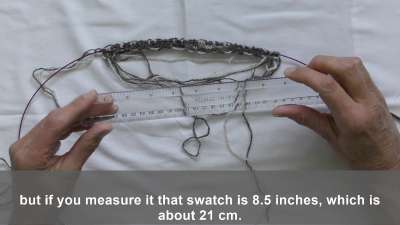

So here I am, 4 ROWS in, how am I going? Well, you won’t be able to see this because the numbers on the ruler are too small, but if you measure it that swatch is 8.5 inches, which is about 21 cm. Remember, I was aiming for something about 6 inches.

I’m not worried about that. The reason I’m not worried about that is it is all very loose around the cast-on. – I’m very loose knitting – this is very looser knitting than I normally doI’ve been knitting a lot looser that normal because I’ve been worried about the stranding and getting myself going. I would expect that in about 4 or 5 more rows everything will have tightened up and I’ll be knitting close to gauge. We’ll see.

The last thing I’d like to talk about with this swatch is that I’ve prepared myself for having to do a second swatch. When I’ve done the two, how can I be sure which one is which? What I have done is tie a few knots in the cast-on tail. It’s a little difficult to see, so I’ll bring it up closer to you. If you look on the end here I’ve got one, two, three knots close together. That tells me it’s a 3 mm needle … but further on I’ve got a further knot here separated from the others so that’s three and one quarter – a 3.25 mm needle. If it was a 3.5mm needle, I’d have done two knots further up, and if it was 3.75 mm there’d have been 3. This is purely so that I can remember which swatch is which if I get more than one swatch. If you are using american needle sizes of course, you only need the one set of knots to tell you what size of needle it is. 2, 6, 8. Of course if you are using very fine needles, once you get to 0, 00 you’ve got a bit of a problem and will need to work out a system.

This is my swatch, 4 rows in. I’ll come back later and we’ll see how I’ve got on, and how I’m matching up to gauge.

Looking forward to the rest of the project

I’ve more or less finished this podcast now. I’ve talked about how I go through assessing the pattern, what considerations I want to make, about the yarn, the tools, the techniques, the size I want to make it, and how I draw the lessons from the gauge swatch. Now, I’ve got to go off, finish the gauge swatch, and I’ll come back in the next podcast to tell you how things have gone.

Where I am at the moment is that I think I want to make the 45 inches size, which will work aout about 114 cm round the chest. That should give me the ease that I want, because I want it to be loose, but not very loose. I think I’m going to need an extra band of motif on the bottom to give me the extra length that I need, and I’m quite happy with the wool.

The other thing is that I’ve done some calculations that said that if I put in that extra band, am I going to have enough wool? It is very difficult to tell, because this pattern, although it tells the amounts of wool it needs for the various different sizes, has several of the colours that have only one or two balls of yarn that are used. So how do I know whether it is I’m going to need more balls of yarn if I increase the size?

I could just buy an extra ball of every piece of yarn, but it uses several colours, at least 7 colours [actually 10 colours], so that’s a lot of extra yarn to buy if I don’t need it. This is where Ravelry came to my rescue.

In Ravelry, there’s a projects page for this particular garment, and you can see how it has worked out for various people, and some people have put more explanation in their project notes than others. Someone called maevezana [on Ravelry] has put quite detailed notes on. One of the things she has made a note of is how much yarn she actually used in her version of the vest. It is her version, not mine, it is in her size, her gauge, but for the size she knit, she used appreciably less yarn than is called for in the pattern. This tells me that the amounts used in the pattern are only a small part of the ball. You can only buy the yarn in 25g, so there is no point in telling you that you only need 7g of one colour – because you can’t buy just 7g of one colour. For most of the colours, what that set of project notes in Ravelry is telling me is that there will be plenty of yarn and also for the main colours that I am using, I will have only just started the last ball of yarn in that knitting so adding the extra motif, I should have plenty to go on. Famous last words!

If I do end up knitting that extra motif, will I be playing yarn chicken and keeping my fingers crossed that I’ve got enough yarn, or will I have enough yarn to keep going? There’s only one way to find out, and that is to knit the garment and suck it and see.

What am I going to do in the next podcast?

First thing, I’m going to have finished the gauge swatch so I’ll know what gauge I am getting. So rather than talking “I might need this, I might need that” I can say “this is what I am intending to do”.

Once I’ve decided what I’m going to do, I’ll then be casting on. There are a couple of things I’d like to talk about in doing that cast-on. Obviously I’ll be showing you the cast-on technique itself, but I’m also going to be casting on for knitting in the round. There are techinques to help me join in the round and not end up with a twisted cast-on. This can be really annoying, particularly for a project that you’ve cast on over 300 stitches.

Next time I’ll be telling you what I’ve learned from the swatch, and I’ll be talking about the cast-on.

Until then, that’s it from me.

Happy Knitting!

Basic stranded cast-off (T201902)

Show notes for the basic stranded cast-off tutorial

Basic stranded cast-on (T201901)

Show notes for the Basic Stranded Cast-on Tutorial

Sami turf hut (C201817)

This example of a traditional Sami turf hut is opposite the Borderlands Museum in Kirkenes, Norway.

Røros wall (C201816)

Røros in Norway was founded in 1664 as the hub of a copper mining area. No longer active as a mining centre, Røros is designated as a UNESCO World Heritage Site.

Saint Michel d’Aiguilhe (C201815)

Le Puy in France is perched on the top of volcanic outcrops, and Saint Michel d’Aiguilhe appears to be the most delicately balanced building in the town.